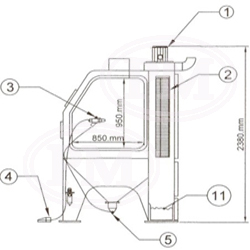

SUCTION BLASTING MACHINE

เครื่องพ่นทราย

| The suction blast machine is designed for abrasive blast cleaning of small parts or components. The system is suitable for surface stripping process, derusting, deburring, etching, aesthetic process mould cieaning etc. Using all kind of abrasive such as glass beads, aluminium oxide, silicon carbide etc. |

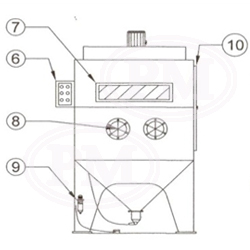

| FEATURES |

| 1. BUILD-IN DUST COLLECTION SYSTEM The dust collector system ensures that only clean and dust free air is discharged to the atmosphere. 2. ABRASIVE FLOW REGULATOR Used abrasive is recirculated continuously throughout the blasting operation An abrasive flow regulator at the base of the hopper of the cabinet controls and ensures the smooth flow of abrasive cabinet controls and ensures the smooth flow of abrasive 3. BLASTING GUN Aluminium alloy body holder complete with NTK Ceramic Nozzle. 4. AIR WASH GUN For use after blasting process - removal of surplus dust and blasting media. 5. USING ALL KIND OF ABRASIVES SUCH Glass beads, Aluminium oxide, Silicon carbide, Steel shot, Steel grit, Cut wire, Zinc shot, Ceramic beads. |